This Page is Under Construction #

Basic Propositions #

- Warmed air pockets ascend

- Air at altitude is cooler than air at ground level

- Rising air pockets generally cool at the same rate as the surrounding air cools with altitude

- Warmed water that rises does not cool like air

- Water can be used as a heat transfer medium

- Using water, cooler temperatures at altitude can be transferred downard while warmer surface air temperatures can be transferred upward

- Geothermal heat temperatures warmer than the surface air temperatures are available by digging into the earth’s surface

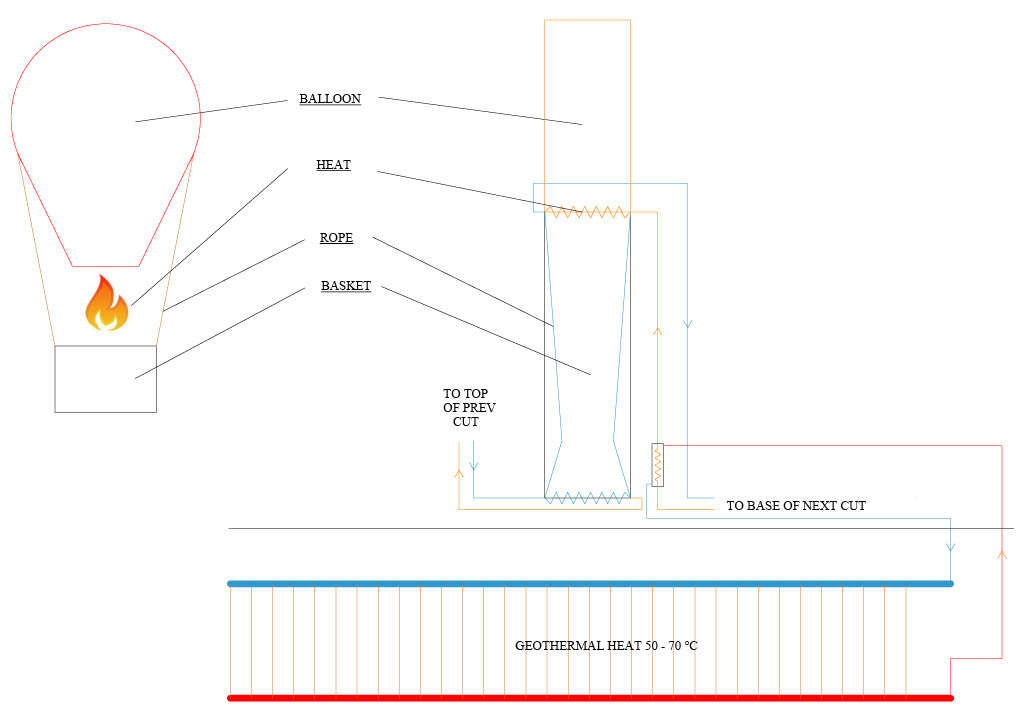

In order to understand how the CHE works, we have to start from something that is generally well understood – the Hot Air Balloon. It consists of the following key components:

A. The Balloon #

– a volume of air that is warmer (less dense) than the surrounding ambient air.

B. The Heat Source #

– a source/reservoir from which to heat the Balloon to above the surrounding ambient air temperature.

C. The Heat Delivery System #

– a delivery system to move heat from the Source to the Balloon

D. The Basket #

– the load lifted by the Balloon that is heavier than the surrounding ambient air.

E. The Rope #

– connecting the Basket to the Balloon

The goal with what follows is to connect elements of the CHE to the Hot Air Balloon in order for you to gain an understanding of how it works.

The Heat Source(s) #

- The surface temperature of the atmosphere, which is warmer than the atmosphere at altitude, and can thus act as a source of heat relative to high altitude air. (from 2 above)

- Geo-thermal (from 7 above)

The Balloon #

- A tall chimney like structure with fabric sides which reaches around 1000m above ground level. Here the air is some 10°C cooler than the air at ground level. This chimney like structure will be called a Convective Uplift Tower (CUT). The top section of the CUT serves as the Balloon. The warmed air in the Balloon rises up the CUT as a result of proposition 1 above.

The Heat Delivery System #

- Water circulating in insulated pipes, with heat exchangers situated in the Source (to collect the heat) and in the Balloon (to deliver the heat). Note that this system will deliver surface temperatures to the Balloon (resulting in warmed air uplift) and simultaneously deliver the cooler temperatures at the Balloon’s altitude to ground level.

The Basket #

- The cooler temperatures delivered to the ground by the Heat Delivery System is drawn into the bottom of the CUT by the uplift of the warmed air in the Balloon. The bottom section of the CUT serves as the Basket. The heavier cooled air (Basket) being drawn up the CUT by the Balloon is cooled further as a result of proposition 3 above.

The Rope #

- The air in the Balloon (top section of CUT) is rising up. The air in the Basket (bottom section of CUT) is heavier than ambient and tends to sink. The sides of the CUT are air tight and do not allow ingress of surrounding air. A low pressure region is established between the rising air in the Balloon and the heavier air in the Basket. This low pressure draws the heavier air of the Basket up with the rising air of the Balloon. The fabric sides of the CUT maintain the integrity of the low pressure region and accordingly serve as the Rope.

Presentation #

Now, having shown that it is possible to create convective uplift using ground level heat transferred to a higher altitude, and that such convective uplift can lead to further cooling within a CUT, we can show you with the following presentation that CUTs can be coupled together consecutively to create even further cooling. The more CUTs that are coupled together, the more cooling is achieved.

Now we have to understand the benefits of cold air. A few other widely understood propositions are required:

- a) Liquid water is more likely to evaporate into water vapor under warm / hot conditions. Warm air thus favors the presence of water vapor in the air.

- b) Water vapor condenses back to liquid water under cold conditions. This is why clouds (tiny droplets of suspended water) occur at altitude where the air is colder. At even higher altitudes, where it is colder still, you may get solid water in the form of snow or hail.

- c) All thermal power stations need condensers to condense the low pressure steam / gas leaving the turbines back into liquid. Most power stations use cooling towers to do this. The cold air generated by the CHE can act as a very effective cooling tower.

So now we can see two potential uses for our CHE. Warm ground level air is drawn into the CUTs and cooled as they enter the bottom. Once they are cooled down enough, the water vapor in this air will condense into liquid form (just as in an A/C system). This condensation occurs directly on the heat exchanger surface (as in an A/C system). Mist also forms in the CUTs as the cold air is further cooled as it rises up the CUTs. The CHE thus produces water condensate out of the ambient air – very much like an A/C system does.

Furthermore, from (c) above, the CHE can act as an effective cooling tower for power generation since it produces a continuous stream of cold air that is colder than ambient conditions – making for more efficient power generation. The heat source for this power generator could even be the ambient air, but the geo-thermal energy below the CHE (see 7 above) can reliably provide higher temperatures (than the ground level air) for more efficient power generation. See OTEC for an example.

How these CUTs are designed (sized) and connected together is not straightforward – it requires careful calculations for the correct dimensions to be established. To see how this may be done, see here.

From this description it can be seen that our CHE has components very similar to other Heat Engines, like thermal power stations. The warm ground level air acts as a boiler / evaporator in that it favors the formation of water vapor from liquid water in the environment. The cold air that is generated by the CHE uplift processes in the CUTs act as a condenser – both by turning the water vapor in the CUTs into fresh liquid water for use as needed, as well as serving as an efficient low temperature condenser for a thermal power plant for electrical generation.